You know the feeling you get when something just works right out of the box? That’s the feeling I got when I did my first engraving with the new Flux beamo laser cutter and engraver. The relatively small footprint beamo uses frickin’ laser beams at different intensities and speeds to engrave or cut multiple materials for DIY projects.

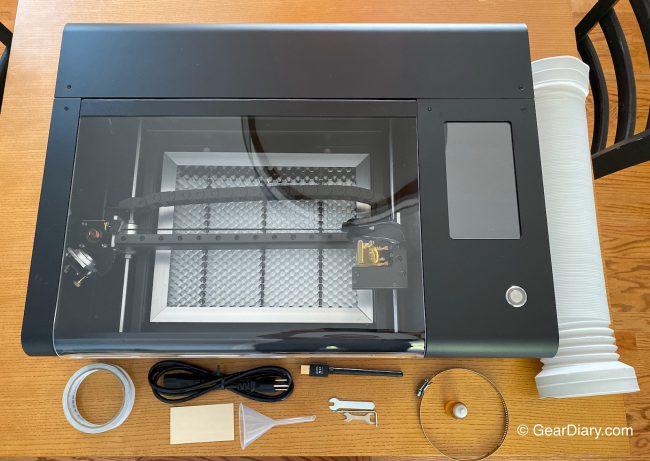

Beamo‘s biggest selling point is its size. While many similar laser engravers are over 32” x 20”, Flux designed beamo to be significantly smaller, at 24.21” x 17.51”. For a device that’s meant to sit on a work surface or tabletop, space savings is a big deal, allowing you to store much more on the same surface as the beamo. The beamo also weighs significantly less than many laser engravers, at 48.5 pounds, making it light enough to take it wherever you need it. Unlike some of the larger units, however, the working area is slightly smaller at 11.81” x 8.27”. You have to take cost into account with units like these, and the MSRP on the beamo is $1,499 compared to one of its closest competitors at $2,495. If you act quickly, you can catch the beamo on Kickstarter for $849!

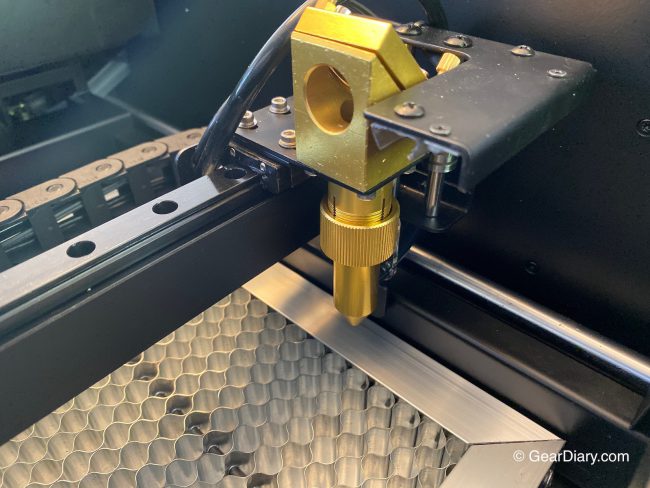

Beamo is equipped with a 30W CO2 laser that can cut through 3mm thick wood, acrylic, and many other materials with a precision clean cut edge. By adjusting the intensity and speed of the laser, you can engrave, score, and etch as well. It’s a really simple premise that’s easy to use even if you’re a complete beginner, especially when matched with Flux’s basic Beam Studio application that’s compatible with Windows, macOS, Linux, and Chrome OS. More on Beam Studio later; both the good and bad.

Tucked inside the beamo, attached to the laser assembly, is a camera that allows you to get a scaled view of the material you’re planning on engraving. This gives you the chance to actually draw your design on the material itself, making sure the design is scaled exactly how you’d like it to be. I found the camera to be really helpful in ensuring my design would come out perfectly as planned. You can also use the camera to capture your hand sketches and turn them into digital files and then engravings.

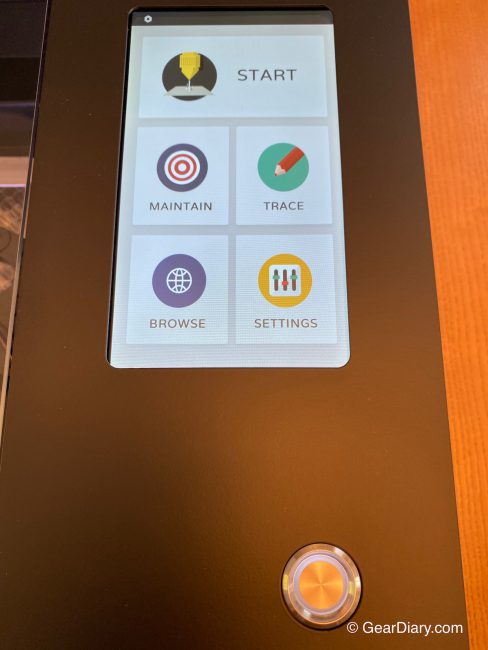

Built into the inner working of beamo is a water cooling system that ensures the unit doesn’t overheat and damage the internal components. Very helpful to avoid a meltdown and a feature that not all laser engravers can claim. Another nice feature is the LCD touchscreen on the unit itself. With the touchscreen, you can perform many functions, including changing settings, browsing previous designs, and starting up the cutting/engraving functions. It looks like there’s a future feature that will allow you to browse the web to download and print using shared designs, but this feature didn’t appear to be working during testing.

The beamo features a pretty decent exhaust fan that helps draw smoke and exhaust from the laser cutting and engraving process away from the project and outside your work area using the included extendable plastic duct. The exhaust fan creates a pretty good vacuum inside the unit in conjunction with the acrylic cover that you can feel when you try opening the cover after a job is complete. While we did have some minor smoke smells in the house while testing, the exhaust fan and duct did a good job removing the majority of the smoke when the duct was routed out the window.

In testing, the Flux beamo was a lot of fun and surprisingly easy to use, assuming the software behaves. I ran into some quirks with Beam Studio on macOS; it will sometimes reset itself or require me to restart the app manually. When selecting the sample beamo image during testing, the language of the application would switch to an Asian language I couldn’t read and would only switch back once I restarted the app. While the application is fairly simple and intuitive, I found there to be some quirks that I had to work through. However, I’m sure they’ll get ironed out over time.

I have to say that I’m really impressed with Flux’s latest laser engraver. The beamo is smaller, lighter, and less expensive than many of its competitors while still performing admirably. While the laser is slightly less powerful than some of its competitors, you only really miss out on the ability to cut through thicker materials or engrave harder surfaces. Beamo is great for the majority of DIY projects, including engraving wood, acrylic, leather, glass, and more.

You can pick up your Flux beamo by backing Flux’s Kickstarter campaign before November 30, 2019. Afterward, you’ll want to purchase directly through Flux.

Source: Manufacturer supplied review sample

What I Like: Easy to learn and use; Powerful laser can cut and engrave a multitude of materials; Simple software; Preview camera; Small form and lightweight

What Needs Improvement: The software isn’t bug-free and could use some updates