You might think it odd for a company like John Deere to be at CES, but after spending an hour with them yesterday, I can completely understand. Even though I’ve spent much of my adult life in an agriculturally-focused town managing a cattle ranch, I’d never paid much attention to the tech being utilized by the farmers in my area to produce food and fiber for human consumption. My eyes have now been opened.

Deere & Company has been making farm equipment since 1837, when its founder, John Deere, developed the first commercially successful, self-scouring steel plow. The plow that he smithed that was so revolutionary, “hundreds of people gathered at the farm of Lewis Crandall near Grand Detour to see the young blacksmith test his new product.” But that was just the beginning.

This is John Deere’s third year at CES. They have found it to be a tremendous platform for raising awareness of the technology, IoT, electrification, and singulation with their overall platform with agriculture and sustainability while feeding the world. When you think about farmers and the tremendous challenges and opportunities that they have — including the fact that they’re going to have to provide a greater than 50% uptake in food production to keep up with the projected nearly 9 billion people the world will have in the next 25 years or so — you have to take a moment to appreciate the enormous task ahead for farmers around the globe.

Something to consider with farmers is how timing is literally everything. For instance, a midwestern farmer has about a ten-day window in the spring to get their seeds in the ground. It could be corn, soybeans, or something else. If the weather doesn’t cooperate, that window shrinks to even fewer days. So when John Deere talks about agriculture and precision, and the technologies that they are putting on their tractors and planters, it is essential for the company to deliver solutions that are easy to use and that provide maximum uptime, so farmers never miss that window.

Farmers also have to deal with unimaginable uncertainty that drives the decisions they have to make. Through John Deere’s data platforms and all of the data that they make available to farmers in real-time, they aim to take some of the guesswork out for farmers so that they can make the most informed decisions — not just the ones that will impact them as they get the seeds in the field, but also when they have to fertilize their crops a few weeks later and eventually harvest them months later.

So while farmers are focused on getting through this year’s crops, John Deere is actively searching for ways to help them take some of the guesswork out of today’s important decisions as well as the ones they will need to make in five, ten, or even twenty years.

A farmer’s legacy is his land, so soil health and sustainability are always at the forefront of their mind. On top of getting the maximum production that they can from their land while they are actively farming it, a priority for them is making sure that they keep the soil in good condition for the next generation and the ones after that. John Deere helps provide them the equipment, data, and information that they need to do this.

The John Deere Experience at CES

Yesterday, I used a pre-loaded Oculus headset that John Deere had loaned to me for CES to experience a virtual demonstration. My guide was Jenny Ose, the Director of Marketing and Shared Services for John Deere. She started our tour with an overview of what today’s farmers have to deal with to grow and harvest the produce that we buy in grocery stores and the cotton that we find in our clothing. It was again driven home that our food doesn’t start as the raw vegetables that we buy at the grocery store, and our clothing doesn’t just magically appear on department store racks; it all starts with one seed at a time.

My tour started with a huge John Deere tractor with a large planter in tow pulling up to me. The first demo was how the tractor and the planter constantly communicate with each other, feeding information back and forth wirelessly via hundreds of sensors on each piece of equipment. This gives the farmer about what is happening on the planter behind them and what is happening in the tractor as they sit in it.

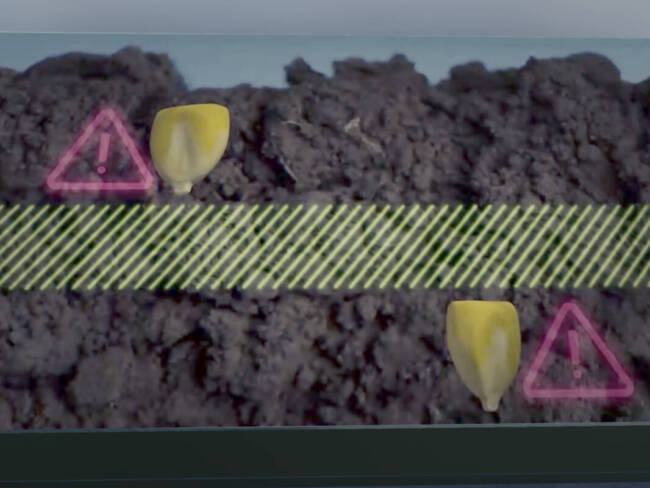

I was directed to the back of the planter to look at one of the row units. A single row-unit on a planter places over 100 seeds per second at 10mph, and there are many row units on the back of the planter. The planter doesn’t just have to precisely drop the seed in the ground at the precise depth and spacing; it also has to open a trench for the seed to go into before the seed is planted and gently cover the tranch after each seed is placed with just enough soil that the seed will be able to grow properly. Everything is automated, from the precision to the depth, to the spacing.

I was then virtually taken 10-12′ below the ground, where I was shown a demo that illustrated how important the precision placement and the depth at which a corn seed, in this example, was placed when planted meant the difference between whether a seed would require more energy and nutrients to survive (if planted too deep) or whether it would not grow a deep, strong root (if planted too shallow). In both cases, the yield would be affected.

The planting conditions have to be personalized down to that farmer’s particular field, wherever it might be in the world. Everything has to be personalized — including current moisture levels — to get the maximum yield while preserving the soil’s integrity for the future.

What I watched next was rather surreal; in slow motion, a tractor and a planter drove over me, precisely planting each seed with the planter’s row units. This was impressive enough, but hitting a button that said “Real-Time” showed me how quickly all of this precision must occur — with over 2800 seeds being planted per second in the “soil” above me, each of them perfectly placed.

If the seeds are planted too close to one another, the seeds will draw on each other’s energy, competing, and won’t reach their full potential. If the seeds are placed too far from one another, weeds will grow. Planting placement is literally one of the most important things for farmers to consider, no matter where they are farming or what they are planting.

I was next transported to a tractor cab’s interior, where farmers can spend as much as 20 – 24 hours in the cab during a plant. John Deere has spent a lot of time on their tractor cabs, not just trying to provide comfort and reduce operator fatigue, but to improve the overall user experience. All of the data from the ground, the planter, and the tractor are displayed at the farmer’s fingertips in the cab. When a farmer is sitting in a tractor, everything that matters (beyond steering straight down the proper rows) is happening behind them.

Over 20 years ago, John Deere developed their auto-steer technology; to illustrate what a game-changer this is, I was directed to activate Self-Drive. I virtually put my hands on the tractor’s steering wheel and tried to drive straight down the row; I did not do well. Jenny asked me to imagine driving a tractor for hours on end, trying to stay in a row without running over a plant or into another row; I could imagine being skilled enough to accomplish this, but it sounded miserable.

After I activated auto-steer, I could see how farmers of every skill level and age can get this done — and even take a break to eat a sandwich or take a drink of water while planting.

John Deere has recently introduced technology that is smart enough that when a tractor comes to the end of a row, it will automatically slow down, turn off the putting of seeds into the ground, lift the planter from the ground, and then turn the tractor and planter without running over any of the other rows. The tractor then automatically lines itself into a new row, puts the planter back down on the ground, starts dispensing seeds again, and then speeds back up to 10mph … all of it done automatically!

This is all possible with the power of GPS and all of the automation that John Deere has brought to farmers.

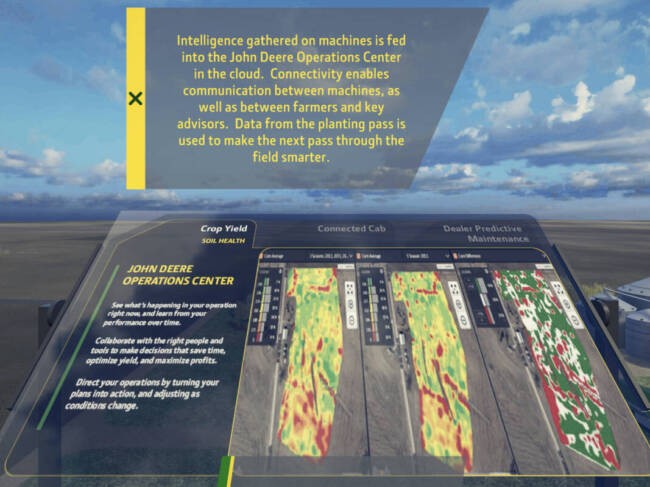

I was next taken to a bird-eye view of the farm, where I could see several tractors working in the field. I was given a demonstration of crop-yield data that these advanced machines generate. There was a series of maps showing red, yellow, and green areas. These are the data maps produced for that particular field that show areas where issues, such as soil dryness or other things, affected the yield. Using these produced maps, farmers can make adjustments in the following years to do as much as possible to eliminate the red areas to have the best possible harvests.

The data is generated for the farmer and belongs solely to them, but they can also consent to share it with their crop advisor, John Deere dealer, or seed salesman. Or they can opt to keep all of those maps, crop, and yield data for themselves.

That data is generated for every single field. The customers map every single one of their fields once; when they go into a different machine, its GPS will recognize which field they are in as the boundaries are already set, and they will use that map from year to year.

A farmer’s John Deere machines will talk to each other, too. So if, for example, you have a farmer with multiple machines running at any given time, and one of the operators should try to go into an area that has already been planted, the machine will automatically stop planting. If the farm owner has to leave while hired workers are planting his fields, he can use an app on his phone to see exactly where each tractor is running and what is happening from an acreage standpoint.

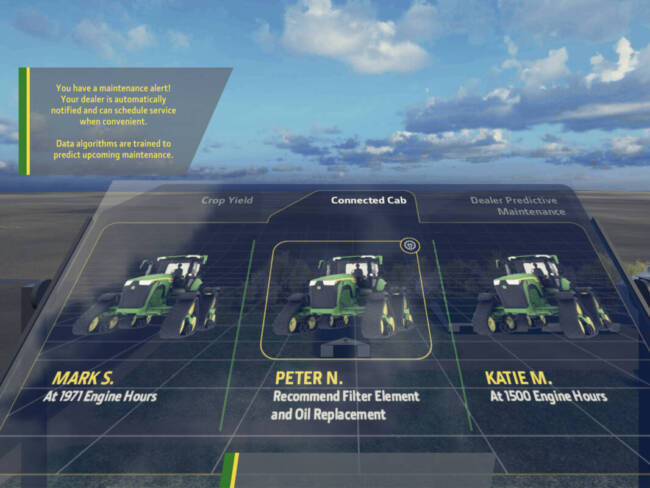

Even further, the machines can predict when they will need maintenance. With embedded John Deere Link technology, if a filter needed to be replaced or more oil were to be needed soon, the machine would automatically send a notification to the operator, as well as to the John Deere dealer so that they could load any parts needed and send them directly to the farmer so that the farmer would have the proper supplies on his farm to reduce or eliminate down-time.

If there is a failure that is indicated as about to happen in the next 10 hours, the farmer and the John Deere dealer will get an Expert Alert, and a John Deere technician will meet the farmer at their field and perform the repair, again saving any down-time.

Last year alone, John Deere sent over 110,000 Expert Alerts to customers throughout the world, letting them know that a technician was on the way with the proper parts to stop them from having any unnecessary down-time. The goal is always to keep the farmer up and running during the critical times of the year.

Knowing where customers’ tractors, planters, and combines are in this manner allows John Deere to be proactive with parts, maintenance, and repairs. This system has come in very handy during the pandemic because it eliminates unnecessary face-to-face touchpoints that might have been needed in the past. Before this preventive technology, John Deere service agents might have driven out to the farmer’s field during the planting or harvest just to check-in. They would have had to hop in the cab and check in with the farmer to make sure that everything was going well, which is dangerous now.

John Deere had sent me a planter and a selection of seeds to choose from before our meeting. While I was distressed that my single soybean seed hadn’t yet sprouted — Jenny assured me that same stress — magnified — was exactly what every farmer feels a few days after they have planted a field. The difference between our situations obviously being that I could try planting another seed, but a farmer would go bust if their crops didn’t grow.

After hearing about all of the technology present and the services offered, I had one question … what would a tractor and planter like the one in my demo cost? My guess of $250,000 was laughably low. A tractor and planter like I drove, with all of the discussed technology, runs around $800,000 brand new. And that’s just one of many pieces of equipment necessary to run a farm.

Obviously, any farmer who invests that type of money has to find a return, which is why John Deere does so much to help these farmers maximize their yields and enhance sustainability. Everything on the equipment is planned to work with the type of soil that the farmer has in his field, down to the type of tracks (which prevent soil compaction) or wheels on the machine he buys.

It’s really incredible, and I had no idea. I came away from this experience with a new respect for the investment and time put in and sacrificed by farmers everywhere to ensure that their crops end up in our grocery and clothing stores.

If you’d like to experience something similar to what I did, you can take the 360º experience or explore the other interactive highlights on the John Deere CES microsite.